Micron precision is always required for micro machining applications with the inclusion of drilling, reaming and line boring. To deliver such accuracy, Schunk now offers a hydraulic expansion toolholder where a run-out accuracy of 0.000 mm can be quickly achieved.

Micron precision is always required for micro machining applications with the inclusion of drilling, reaming and line boring. To deliver such accuracy, Schunk now offers a hydraulic expansion toolholder where a run-out accuracy of 0.000 mm can be quickly achieved.

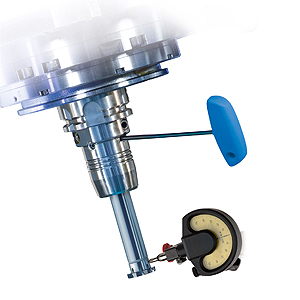

The new TENDOzero is equipped with four lateral set-screws that directly adjust the tool shank. The angular position of the tool is corrected and the run-out is precisely adjusted. With this precision toolholder, even demanding applications with tight tolerances on the form, position and surface finish can be rapidly and reliably machined.

Tool costs are reduced by up to 50%

In contrast to conventional solutions that work with compensation adapters or rings, the set-screws of the TENDOzero are directly integrated into the precision mounting. Interfering contours are optimized and the adjustment process is simplified with an excellent run-out accuracy guaranteed. With a Torx-plus key, the angular position of the clamped precision tool is corrected and run-out is adjusted. Compensation of the spindle run-out errors are conducted directly at the machine, so that machine, toolholder and tool are perfectly aligned.

When using high-quality tools with PCD or CBN cutting edges, quality and dimensional accuracy of the workpiece increases and the tool is protected from damage. Furthermore, the excellent vibration damping of the hydraulic expansion toolholder assures an even cut and micro blowouts on the cutting edge are noticeably minimized, thus increasing tool life drastically. Comparative measurements confirm that with the TENDOzero, tool service life is extended by up to 50% with machine spindle service also improved.

The coolant supply to the cutting edge is also very sophisticated. As well as having conventional cooling from the outside, the TENDOzero allows an internal coolant supply. In a slightly modified version, the TENDOzero also permits minimum quantity lubrication (MQL). With all these features, the ‘Zero-Micron-Toolholder’ paves the way for modern, highly efficient reamers and drills that are utilized in extremely accurate machining applications. The clamping diameter can be reduced down to 3 mm by using intermediate sleeves. The run-out accuracy of 0.000 mm is also adjustable.

As with all SCHUNK hydraulic expansion toolholders, a simple Allen Key is all that is needed for a quick tool change. The clamping screw is turned to the stop and the tool shank is surface clamped. After every tool change, the run-out accuracy is re-adjusted to 0.000mm again. The precision mounting of the TENDOzero is available for the interfaces HSK-A63 and 100, SK40 and 50, BT40 and 50, as well as the CAPTO C4, C5 and C6.