Few places, and few industrial sectors, present greater competitive challenges than the Rustbelt does these days. There’s less business around for machine shops in the region, but those that work smarter can survive. With the right circumstances and decisions, they might even thrive.

Few places, and few industrial sectors, present greater competitive challenges than the Rustbelt does these days. There’s less business around for machine shops in the region, but those that work smarter can survive. With the right circumstances and decisions, they might even thrive.

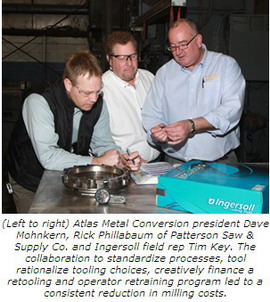

That’s happening at Atlas Metal Conversion (formerly Smith Machine) in Eighty-Four, Penn., about 40 miles south of Pittsburgh. To retain their business, the company had to reinvent itself and, not surprisingly, bid a lot more competitively in terms of price and delivery. So the shop owners brought in a new president with new ideas. Dave Mohnkern came aboard last April, and one of the first things he did was to lead a retooling of the shop’s mainstay milling practices. Today their milling of alloy billets runs 3-5 times faster and delivery times have been cut from 4-5 days to 2-3 days. And, 90% of deliveries are on time. Most important, Atlas has broadened its customer base and improved the bottom line.

The retooling centered on button cutters and tangential mills from Ingersoll Cutting Tools, with which Dave had great success at a shop where he formerly worked. Mohnkern also worked with the local Ingersoll distributor, Patterson Saw and Supply, to finance the conversion as comfortably as possible.

The 25-man specialty shop runs 24/5 to condition as-cast alloy steel, tool steel, and stainless steel billets and hot-rolled titanium slabs for secondary finishing. Principal operations are planer milling to remove 0.25-0.50 in. from all sides of the mill products. Most of the shop’s seven machines are heavy-duty planer mills with 30-40 HP spindles – not the latest but certainly still tight. The other principal operations at Atlas are grinding and sawing.

The 25-man specialty shop runs 24/5 to condition as-cast alloy steel, tool steel, and stainless steel billets and hot-rolled titanium slabs for secondary finishing. Principal operations are planer milling to remove 0.25-0.50 in. from all sides of the mill products. Most of the shop’s seven machines are heavy-duty planer mills with 30-40 HP spindles – not the latest but certainly still tight. The other principal operations at Atlas are grinding and sawing.

Machining mill products fresh from the melt shop or first-stage hot rolling is tough, dirty, unpredictable work. The billets and slabs are sometimes massive, often inconsistent dimensionally, and almost always studded with scale and melt-shop grit. It’s the kind of work that can pop an insert or wreck a tool the minute you turn your back. The normal instinct on the shop floor is to ease back on the feed or depth of cut to avoid such catastrophic failure and the resultant scheduling delays – and having to duck the “shrapnel” of a broken insert chip. Sales representatives’ normal instinct is to build a generous margin for error into every bid.

It was real-life experience that enabled  Dave to lead the retooling with confidence. In his previous job, he had completed an exhaustive evaluation of milling tools. It covered trials with more than 10-15 different mills from 10 leading tooling brands – on essentially the same kind of work. By far, the Ingersoll mills came out on top, so he knew they’d be winners at Atlas, too. “In my 19 years in the business, I’ve never seen any mills cut as fast as the Ingersoll button and tangential mills,” he said.

Dave to lead the retooling with confidence. In his previous job, he had completed an exhaustive evaluation of milling tools. It covered trials with more than 10-15 different mills from 10 leading tooling brands – on essentially the same kind of work. By far, the Ingersoll mills came out on top, so he knew they’d be winners at Atlas, too. “In my 19 years in the business, I’ve never seen any mills cut as fast as the Ingersoll button and tangential mills,” he said.

However, at Atlas he realized that the task involved building trust in the new practices (and a new leader) among machine operators as well as to select the right tool. “When you’ve seen tools fail on large-scale and costly materials, naturally you’re going to take a ‘show me’ attitude toward an unfamiliar tool or a new standard practice,” Mohnkern said.

Real-world trials

So he commissioned new “live” trials, limited to 5-7 cutters from 2-3 providers this time, to update his “data bank” and let Atlas operators actually see the differences for themselves. Not surprisingly, the Ingersoll tools won again. The test material was stainless steel 13-8. Inserts lasted two to eight times longer at identical machining rates, indicating headroom to speed the process up.

Atlas undertook the retooling one step at a time, being very thorough. They started the tests in November, factored in a lot of operator training with heavy Ingersoll involvement, and finally went operational in January 2011. “We were out to not only run faster, but to run predictably faster – predictably enough to bid more aggressively and still be sure we’re making a fair profit,” explained Mohnkern. “With a more predictable process, we can get by with a smaller margin of error in bidding.”

His next goal was to pick up some additional savings by reducing the tool and tool vend or count. “By standardizing on fewer tools able to handle a wider variety of work, we benefit three ways,” Dave recounted. “Tooling inventory costs, training costs, error sources: they all go down. Again, we leverage these gains in our bidding.”

or count. “By standardizing on fewer tools able to handle a wider variety of work, we benefit three ways,” Dave recounted. “Tooling inventory costs, training costs, error sources: they all go down. Again, we leverage these gains in our bidding.”

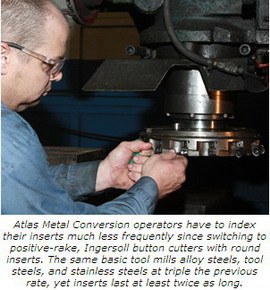

The trials showed that, with a single Ingersoll cartridge-type button cutter, Atlas could improve milling of all the alloy steels, stainless steels, and aerospace alloys. Once they optimized the process, cycle time dropped by 3-5 to 1, depending on the alloy. For instance, taking 0.25 inch off all six sides of a 10-in. cubical billet of 13-8 material took less than one shift, versus 2.5 shifts before. Edge life has doubled, on average, on cutters where dead time for indexing averages 20-30 minutes.

Like its predecessor, the Ingersoll button cutter is a 12-in. facemill with 14 inserts. It makes chips faster because it handles much deeper cuts, completing the pieces with fewer passes. The  main differences in cutter design are round inserts (stronger than the previous rectangles), and positive-rake cutting geometry that reduce cutting forces. The previous cutter had a negative-rake.

main differences in cutter design are round inserts (stronger than the previous rectangles), and positive-rake cutting geometry that reduce cutting forces. The previous cutter had a negative-rake.

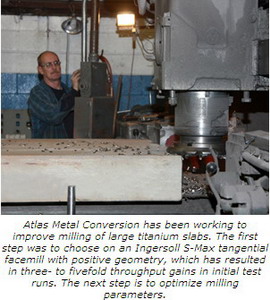

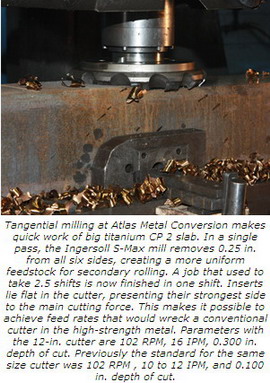

Next, Atlas turned to improving the titanium cutting process, with the transition and retraining beginning in January. A typical titanium CP 2 slab measures 52×266×7 inches. It may arrive as-cast or with one rough hot-rolling pass. This material turns out to require a completely different tool than the alloy steels because of the higher cutting forces it needed. Accordingly, Ingersoll’s Tim Key recommended a tangential “high shear” face mill. Testing so far indicates that an Ingersoll tangential S-Max mill will generate about the same margins of improvement in titanium as the button cutter did in the ferrous metals.

Unlike its predecessor, the Ingersoll S-Max mill orients the inserts tangentially rather than radially in the pitch circle, and at a high positive rake. This arrangement presents the insert’s strongest cross section to the main cutting force vector, enabling much faster feeds and higher depths of cut without risk of tool damage. Moreover, the high-pos presentation geometry reduces cutting forces even at higher feed rates. Cutting is more a cleaving than scraping ac tion.

tion.

Comprehensive training, early buy-in

From the very outset, Dave Mohnkern integrated very thorough operator training into implementing the new standard practice. He knew that, in the real-life job shop environment with “one off” workpieces, no hardware would succeed without an early buy-in from the machine operators. Accordingly, Mohnkern, Tim Key, and Rick Phillabaum of Patterson Saw & Supply Co. agreed on a retraining program that combined group instruction in the classroom with one-on-one mentoring on the shop floor with personnel from all shifts.

An Ingersoll training specialist kicked it off with a six-hour classroom course for all shifts, covering standard procedures for handling Ingersoll cutters, from nomenclature to indexing. Then, Key personally set up the new tooling and parameters on every machine. Thereafter, an Ingersoll specialist from the home office stayed on-site for a full week to work with every operator and answer all questions. “Tim and Rick did it all,” Mohnkern said.

“The work requires a high degree of operator skill and judgment because every piece is a little different,” said Ingersoll’s Tim Key. “Today’s billet has more inclusions and scale than the one we ran yesterday. That’s the nature of cast material coming from a melt shop. Dimensions can vary up to a quarter of an inch over the surface area of a titanium slab. That’s why the training was so important. This is the very opposite of widgets-in-the-bin production.”

Apparently, the reinvention at Atlas has paid off. “Because we’ve cut costs and delivery lead times and established standards we believe in, our bids are more aggressive, business is picking up nicely as a result and profitability is protected,” concludes Mohnkern. “And it all stems from a very thorough evaluation of tooling choices, partnering with a supportive tooling provider, and quality training that the people doing the work can trust. Without Tim’s and Rick’s help, we would not have been able to have successfully come this far with our new expanded customer base.”